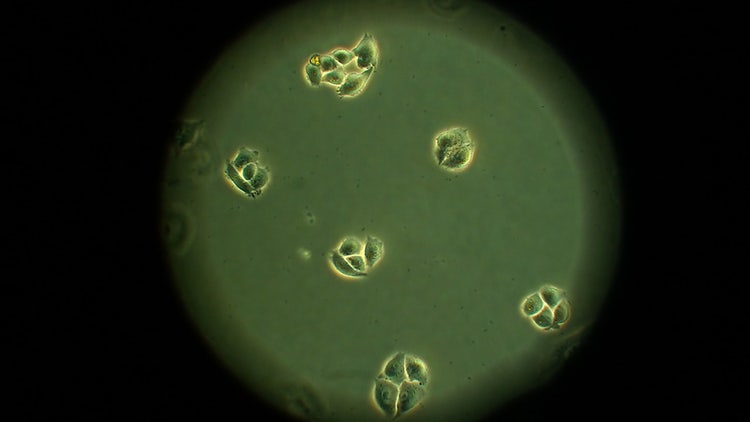

Introduction to CHO Cells

Chinese hamster ovary (CHO) cells are the benchmark for industry-scale production of recombinant proteins for antibodies and other biotherapeutics. They are the most preferred mammalian host cells for protein production because of their similarities to human cell lines, which makes their products highly relevant to biomedical research. They are also easy to cultivate and adapt to different culture media, generating substantial yield from small sample volumes. All these advantages granted CHO cells the nickname "The Mammalian E. Coli."

History of CHO Cells

The use of Chinese hamsters in biomedical research dates to the 1920s, when they were inoculated against various strains of pneumococci, Leishmania, and many other disease-causing organisms¹. Their potential as a disease modeling tool was soon recognized internationally, as it was also discovered that Chinese hamsters harbored low chromosome counts, lending them to genomic studies².

The development of cell lines from Chinese hamsters took place in the 1950s. Geneticist Theodore Puck obtained a single adult female and extracted cells from its ovary, expanding them in a petri dish, giving rise to the first CHO cell line2. The following decades saw the skyrocketing of CHO variants with increasing growth, productivity and safety profiles. The advancements in CHO cell development also coincided with the discovery of recombinant proteins, where engineered DNA sequences transfected into cell lines would produce large quantities of a protein of interest. It soon became evident that CHO cells constituted an ideal platform for rapid and scaled biologics manufacturing. In 1987, tissue plasminogen activator became the first CHO-derived therapeutic approved by the FDA, and it was used for treating clot-inducing ailments and cardiovascular diseases³.

In 2022, More than 50 FDA-approved therapeutic proteins have been derived from CHO cells⁴.

Advantages

CHO cells became the gold standard in protein production due to several advantages over other mammalian or bacterial cell lines.

Production of Biologically Relevant Complex Proteins

Chinese Hamster cell structure is similar to human cell structure, which makes it an ideal platform for pharmaceutical production for use in humans. Unlike many other cell lines, including E. coli, CHO cells can induce post-translational modifications (PTM) in proteins, particularly glycosylation, which occurs in most human proteins. Thus, PTM in CHO cell proteins can determine qualities, such as protein biosimilarity, bioactivity, and immunogenicity.

Ease of Growth and Production

CHO cells are easy to grow and cultivate in large-scale bioreactors, seamlessly adapting to varying environmental conditions, such as oxygen levels, temperature, and pH. More importantly, they were shown to grow substantially in animal-free and serum-free suspension media, which makes them very cost-effective and regulatory-compliant compared to other cell types. On average, one liter of CHO cell culture can yield 3-10 grams of recombinant therapeutics⁵.

Ease of Gene Amplification

Although some cell lines may suffer from an incorrect integration of the transgene that decelerates protein synthesis, CHO cells are amenable to genome engineering systems that optimize therapeutic protein production. Throughout decades, scientists created several CHO variations through genetic cell engineering methods and selection systems to generate stable clones with optimized production rates.

Well-established Safety and Regulatory compliance

With Chinese Hamsters having acquired resistance against many human viruses, CHO cells possess viral immunity that circumvents viral contamination in the cell culture, thus mitigating production losses and biosafety issues. This factor, along with bio-similarity to human cells, makes CHO cells widely established and accepted by regulatory agencies.

Applications

The versatility and robustness of CHO cells make excellent tools for various applications:

- Biopharmaceuticals: CHO cells can be engineered to produce therapeutic recombinant proteins and vaccines.

- Drug Discovery: Drug discovery pipelines can benefit from CHO cells to perform drug screening and toxicity assays, as well as PK/PD experiments.

- Functional genomics: CHO cells are ideal for studying gene functions through knock-in, knock-out, and knock-down experiments.

- Other industrial applications: Besides biopharmaceuticals and cell biology studies, CHO cells are also instrumental in biomaterial production for food, cosmetics, and biofuels.

CHO cell line development process

In CHO cell line development, it is essential to establish a stable clone that thrives in controlled bioreactor environments. A typical CHO cell line workflow includes the steps outlined below:

- Transfection: CHO cells are stably transfected with a recombinant plasmid that encodes the protein of interest. The plasmid enters the nucleus and integrates into the host DNA.

- Selection and Clonal Screening: The protein expression level might significantly vary among cells. Therefore, the CHO cell clones with high expression levels must be selected and isolated.

- Characterization and validation: The protein production efficiency of the selected clones is confirmed via high-throughput cell screening and sorting methods.

- Expansion: The ideal clones are expanded in a serum-free fed-batch culture containing nutrients and growth factors.

- Large-scale Production: The CHO cell clone with the highest efficiency is selected as the industrial-scale production cell line.

- CHO cell banks: Cell banking revolutionizes CHO cell manufacturing by standardizing stable cell transfection and culturing. CHO cell banks established through rigorous quality control procedures provide researchers with stably transfected CHO cells and optimum serum-free culture media, ensuring GMP compatibility in CHO cell manufacturing.

CHO Cell Engineering

One of the main advantages of CHO cells is their amenability to cell engineering, which helps maximize protein production. This is achieved by genome-editing methods, favoring the ones that promote growth and productivity.

Site-Specific Transgene Introduction

Random integration of transgene means that the resulting CHO clones possess varying protein expression. Researchers can ensure reliable and consistent protein production by integrating the transgene into a specific chromosomal locus that enables high expression. This hotspot can be identified through whole-genome sequencing and targeted via several strategies. Gene targeting methods include:

- Recombinase-mediated cassette exchange⁶

- Meganucleases⁷

- Artificial Chromosome Expression (ACE) Systems⁸

- CRISPR/Cas9 gene editing⁹

Gene Introduction/ Overexpression

Overexpression of the gene of interest can be accomplished by exploiting several cellular pathways. Examples include:

Glycosylation

Although CHO cell-derived proteins undergo post-translational modifications such as glycosylation, the resulting glycoproteins are not always identical to human glycoproteins and can cause adverse effects. Researchers and manufacturers can address this issue by transfecting CHO cells with glycogenes that encode glycosyltransferases that are not inherent to CHO cells. For example, ST6Gal gene transfection was used to increase N-glycan sialyation of CHO cell proteins to improve their therapeutic potential¹⁰.

Cellular Metabolism

Optimizing the expression of the genes partaking in cellular metabolism can improve productivity and prolong the CHO cell life span. Metabolic engineering has been used to enhance the rate of nutrient consumption and toxic clearance¹¹

.

Anti-apoptosis

Cell death can hinder the viability of highly efficient CHO cell clones. Overexpression of anti-apoptotic genes can circumvent premature cell death. Researchers exploited the anti-apoptotic mechanisms in cancer to identify genes that can inhibit cell death, such as apoptosis caspase inhibitor (AVEN), X-linked inhibitor of apoptosis, Fas apoptotic inhibitory molecule (FAIM), and myeloid cell leukemia 1 (MCL-1)¹².

Proliferation

Gene overexpression can accelerate cell growth and proliferation to increase production rates. Overexpression of pro-proliferative genes, such as valosin-containing protein (VCP)¹³, was shown to enhance cell viability without the need for additional nutrients.

Cellular Productivity

Cellular productivity can be enhanced by overexpressing genes responsible for protein biosynthesis, such as protein kinases, e.g., mammalian target of rapamycin (mTOR)¹⁴. This strategy can especially be beneficial for proteins difficult to express¹⁵.

Gene Knock-out

Besides the overexpression of genes contributing to cell viability and productivity, the knock-out of disadvantageous genes can also improve yield. Targeted genome-editing approaches, such as CRISPR/Cas9 and zinc-finger nucleases (ZFNs), are instrumental in switching off genes to improve yield. Pathways and genes targeted for knock-out experiments include pro-apoptotic genes and glycosylation (e.g., to minimize fucosylation for improved efficacy¹⁶). Furthermore, the CRISPR/Cas9 editing system has been employed for the simultaneous knock-out of multiple genes and pathways¹⁷.

RNA-based Gene Silencing

RNA interference (RNAi) mechanisms can be applied to silence genes without altering the genome. Small-interfering RNA (siRNA) is employed to target and inhibit mRNA involved in several genes and pathways.¹⁸'¹⁹'²⁰ Similar to knock-out studies, knock-down experiments also target apoptosis, fucosylation, sialidase, lactate accumulation, and several other genes that dysregulated cytoskeleton, intracellular trafficking, and secretion.

microRNA Engineering

microRNAs (miRNAs) are employed in CHO cell engineering due to their ability to regulate multiple signaling pathways that maintain cell integrity and protein biosynthesis²¹. Next-generation RNA sequencing methods are invaluable in identifying miRNAs paramount to modulating gene expression related to cell cycles, metabolism, cell death, and protein synthesis.

See how Danaher Life Sciences can help

FAQs

Why are CHO cells so popular in the pharmaceutical industry?

CHO cells are popular because:

- They can produce large quantities of recombinant proteins.

- They maintain stable protein production over extended periods.

- They can be adapted to grow in different culture conditions.

- Their genetic and physiological properties are studied extensively; thus, they have high safety profiles.

Can CHO cells be used for gene therapy?

Yes, CHO cells can be leveraged for producing viral vectors, such as adeno-associated viral vectors (AAVs), to deliver therapeutic genes to target cells²².

What are the optimum conditions for CHO cells?

The most optimum conditions align with those of the human body, e.g., 37°C, pH 7.0-7.5, and 5% CO2²³

Can CHO cells be cryopreserved?

Several studies concluded that CHO cells can be cryopreserved for increased longevity without disrupting their integrity and protein biosynthesis machinery.

What are the main challenges associated with using CHO cells?

Some challenges include:

- Glycosylation patterns: CHO cells may produce proteins with different glycosylation patterns from human cells, which affect their efficacy and safety.

- Genetic instability: CHO cells can undergo genetic changes that diminish their productivity and alter their characteristics.

- Cost: Culturing and maintaining CHO cells can be expensive.

Are there any alternative cell lines to CHO cells?

Other mammalian cell lines, such as HEK293, BHK, and NS0 cells, are also used for biopharmaceutical production. However, CHO cells remain the most widely used due to their advantages.

References

- Young CW, Smyly HJ, Brown C. Experimental kala-azar in a hamster; Experimental Biology and Medicine 1924;21(6):357–359.

- Puck TT. The genetics of somatic mammalian cells. Advances in Biological and Medical Physics 1957;75–101.

- Vehar GA, et al. Characterization studies of human tissue-type plasminogen activator produced by recombinant DNA technology. Cold Spring Harbor Symposia on Quantitative Biology 1986;51:551–562.

- Zhang JH, et al. Strategies and considerations for improving recombinant antibody production and quality in Chinese hamster ovary cells. Frontiers in Bioengineering and Biotechnology 2022;10.

- Wurm FM and Hacker D. First cho genome. Nature Biotechnology 2011;29(8):718–720.

- Kito M, Itami S, Fuanko Y, Yamana K, Shibui T. Construction of engineered Cho strains for high-level production of recombinant proteins. Applied Microbiology and Biotechnology. 2002;60(4):442–448.

- Silva G, et al. Meganucleases and other tools for targeted Genome Engineering: Perspectives and challenges for gene therapy. Current Gene Therapy 2011;11(1):11–27.

- Kennard ML, et al. The generation of stable, high MAB expressing Cho cell lines based on the artificial chromosome expression (ACE) technology. Biotechnology and Bioengineering 2009;104(3):540–553.

- Lee JS, et al. Site-specific integration in CHO cells mediated by CRISPR/Cas9 and homology-directed DNA repair pathway. Scientific Reports 2015;5(1).

- Bragonzi A, et al. A new Chinese hamster ovary cell line expressing α2,6-sialyltransferase used as universal host for the production of human-like sialylated recombinant glycoproteins. Biochimica et Biophysica Acta (BBA) 2000;1474(3):273–282.

- Tabuchi H and Sugiyama T. Cooverexpression of alanine aminotransferase 1 in Chinese hamster ovary cells overexpressing taurine transporter further stimulates metabolism and enhances product yield. Biotechnology and Bioengineering 2013;110(8):2208–2215.

- Majors BS, et al. MCL‐1 overexpression leads to higher viabilities and increased production of humanized monoclonal antibody in Chinese hamster ovary cells. Biotechnology Progress 2009;25(4):1161–1168.

- Doolan P, et al. Microarray and proteomics expression profiling identifies several candidates, including the valosin‐containing protein (VCP), involved in regulating high cellular growth rate in production Cho Cell Lines. Biotechnology and Bioengineering 2010;106(1):42–56.

- Dreesen I, Fussnegger M. Ectopic expression of human mtor increases viability, robustness, cell size, proliferation, and antibody production of Chinese hamster ovary cells. Biotechnology and bioengineering 2011.

- Pybus LP, Dean G, West NR, et al. Model-directed engineering of ‘difficult-to-express’ monoclonal antibody production by Chinese hamster ovary cells. Biotechnology and bioengineering 2014.

- Zong H, et al. Producing defucosylated antibodies with enhanced in vitro antibody‐dependent cellular cytotoxicity via FUT8 knockout CHO‐S cells. Engineering in Life Sciences 2017;17:801–808.

- Grav LM, et al. One‐step generation of Triple Knockout Cho cell lines using CRISPR/Cas9 and fluorescent enrichment. Biotechnology Journal 2015;10:1446–1456.

- Chari VM, et al. PTSelectTM: A post-transcriptional technology that enables rapid establishment of stable Cho Cell Lines and surveillance of Clonal Variation. Authorea 2021.

- Mori K, et al. Engineering Chinese hamster ovary cells to maximize effector function of produced antibodies using FUT8 sirna. Biotechnology and Bioengineering 2004;88:901–908.

- Sung YH, Lee JS, Park SH, Koo J, Lee GM. Influence of co-down-regulation of caspase-3 and caspase-7 by siRNAs on sodium butyrate-induced apoptotic cell death of Chinese hamster ovary cells producing thrombopoietin. Metabolic Engineering 2007;9:452–464.

- Liu, HN, Dong WH, Lin Y, Zhang ZH, Wang TY. The effect of microRNA on the production of recombinant protein in CHO cells and its mechanism. Frontiers in Bioengineering and Biotechnology 2002;10.

- Nagy, A, et al. Engineered Cho cells as a novel AAV production platform for gene therapy delivery. Scientific Reports 2003;13.

- Xu WJ, Lin Y, Mi CL, Pang JY, Wang TY. Progress in fed-batch culture for recombinant protein production in Cho Cells. Applied Microbiology and Biotechnology 2023;107:1063–1075.

See how Danaher Life Sciences can help

Chinese Hamster Ovary (CHO) Cells